Characterization

Characterization involves analyzing the structure, composition, and properties of materials to understand their behavior and performance. At GTMI, our advanced capabilities enable precise, multi-scale insights that support innovation, quality control, and process optimization across manufacturing sectors.

Elemental Analysis

Elemental analysis involves identifying and quantifying the elemental composition of materials and material systems. Operated within the AMPF as part of the Institute for Matter and Systems, Georgia Tech boasts cutting-edge capabilities in advanced techniques, including precise contaminant identification, material deformulation, automated and microwave digestion systems, and specialized units for detecting elements.

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

This is a new technique at AMPF for elemental analysis of materials and material systems. The Horiba Ultima Expert ICP-OES system provides highly accurate and repeatable results for elements from Lithium to Uranium, with resolution under 5pm and detection levels in the ppb range. We also utilize automated chemical digestion for high throughput, microwave digestion for difficult materials, and additional units for detecting Oxygen, Nitrogen, Hydrogen, Carbon, and Sulfur.

Featured tool: Horiba Ultima Expert ICP-OES – COMING SOON

Materials Properties Analysis

We are equipped with a comprehensive suite of tools to analyze the thermal and mechanical properties of materials. These capabilities are essential for understanding material behavior under various conditions, ensuring optimal performance and reliability in manufacturing processes.

Differential Scanning Calorimetry (DSC)

DSC measures heat flow in materials, providing insights into thermal properties such as melting points, crystallization, and phase transitions. This technique is crucial for characterizing material stability and performance. Featured tool: TA Instruments DSC250 Differential Scanning Calorimeter.

Rheometry

Rheometry assesses the flow and deformation behavior of polymer materials. It supports multiple testing modes, including in-situ UV curing for photosensitive polymers, making it vital for understanding material viscosity and elasticity. Featured tool: TA Discovery HR20 Rheometer.

Dynamic Mechanical Analysis (DMA)

DMA evaluates the mechanical properties of materials by measuring their response to stress, strain, and temperature changes. It is essential for analyzing material stiffness, damping, and viscoelastic behavior. Featured Tool: DMA 850 Dynamic Mechanical Analyzer – COMING SOON.

Microhardness Testing

Microhardness testing determines the hardness of small or thin materials, such as coatings and surface layers, by assessing their resistance to deformation. This technique is important for quality control and failure analysis. Featured tool: Buehler Wilson VH3210 Microhardness Tester – COMING SOON.

anchor

Metrology

Metrology involves the precise measurement of raw materials and finished parts, ensuring accuracy from micro to macro scale. At AMPF, our advanced tools and techniques are crucial for maintaining high standards of quality and consistency in manufacturing processes.

Coordinate Measuring Machines (CMM)

These precision instruments measure the physical geometrical characteristics of an object. CMMs ensure accuracy in manufacturing by verifying dimensions and tolerances, enhancing product quality and consistency. Featured tool: Hexagon CMM.

Non-Contact Surface Profilometry

This is a 3D measurement system that enables fast and simple measurement of built part feature sizes and surface roughness with a resolution of up to 0.1µm. This technique ensures precise and accurate surface characterization without physically touching the part, making it ideal for delicate or complex components. Featured tool: Keyence VK-X3100 3D Surface Profiler.

Particle Size Analysis

This technique determines particle size distribution, crucial for understanding material properties and ensuring manufacturing consistency and quality. Featured tool: Malvern Mastersizer 3000 – COMING SOON.

Microscopy

In collaboration with the IMS Materials Characterization Facility, our microscopy capabilities enable detailed imaging and analysis of samples from 2.5x to 5,000,000x magnification. Our advanced optical and electron microscopy tools are essential for material characterization and quality control.

Optical Microscopy

This capability allows for detailed analysis of metallographic specimens using various imaging modes such as Bright Field (BF), Dark Field (DF), Polarized, and Circular Differential Interference Contrast. It provides comprehensive information on non-metallic inclusions, grain sizes, and phases. Featured tool: Zeiss Axio Observer 7 – COMING SOON.

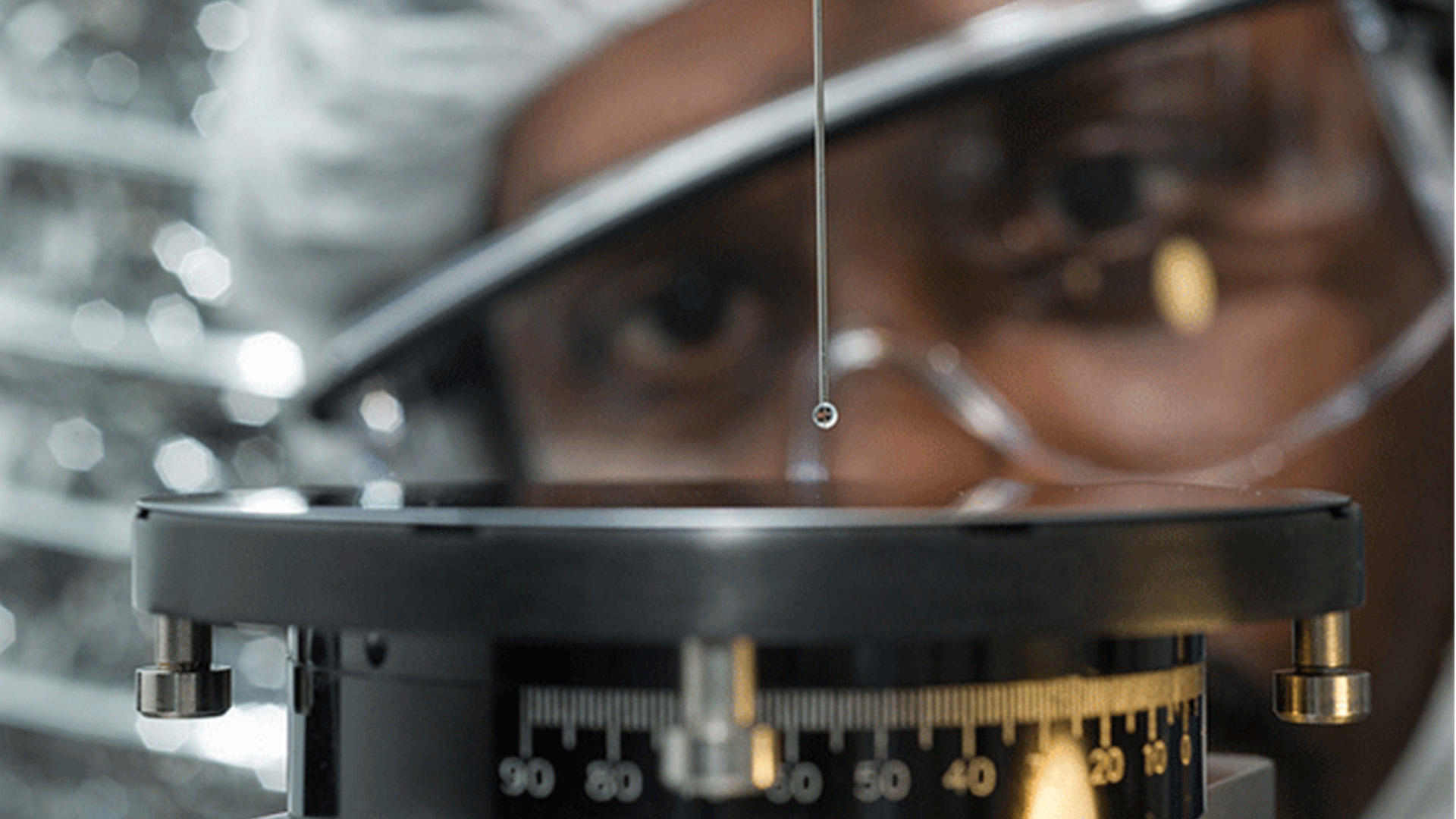

Scanning Electron Microscopy (SEM)

SEM offers high-resolution imaging and crystallographic orientation information. Includes an EDAX/AMETEK Electron Backscatter Detector and TSL OIM analysis software. Featured tool: Tescan MIRA 3 SEM.

Coming soon: In-situ studies of nanoindentation can be conducted with a Nanomechanics InSEM nanoindenter with CSM (continuous stiffness measurement) capability.

Plasma Focused Ion Beam (PFIB) Microscopy (coming soon)

PFIB microscopy is used for Transmission Electron Microscopy (TEM) sample preparation, including 3D characterization, cross-sectioning, and micromachining. This capability is crucial for advanced material analysis and preparation techniques. Featured tool: Thermo Fisher Helios 5 PFIB DualBeam.

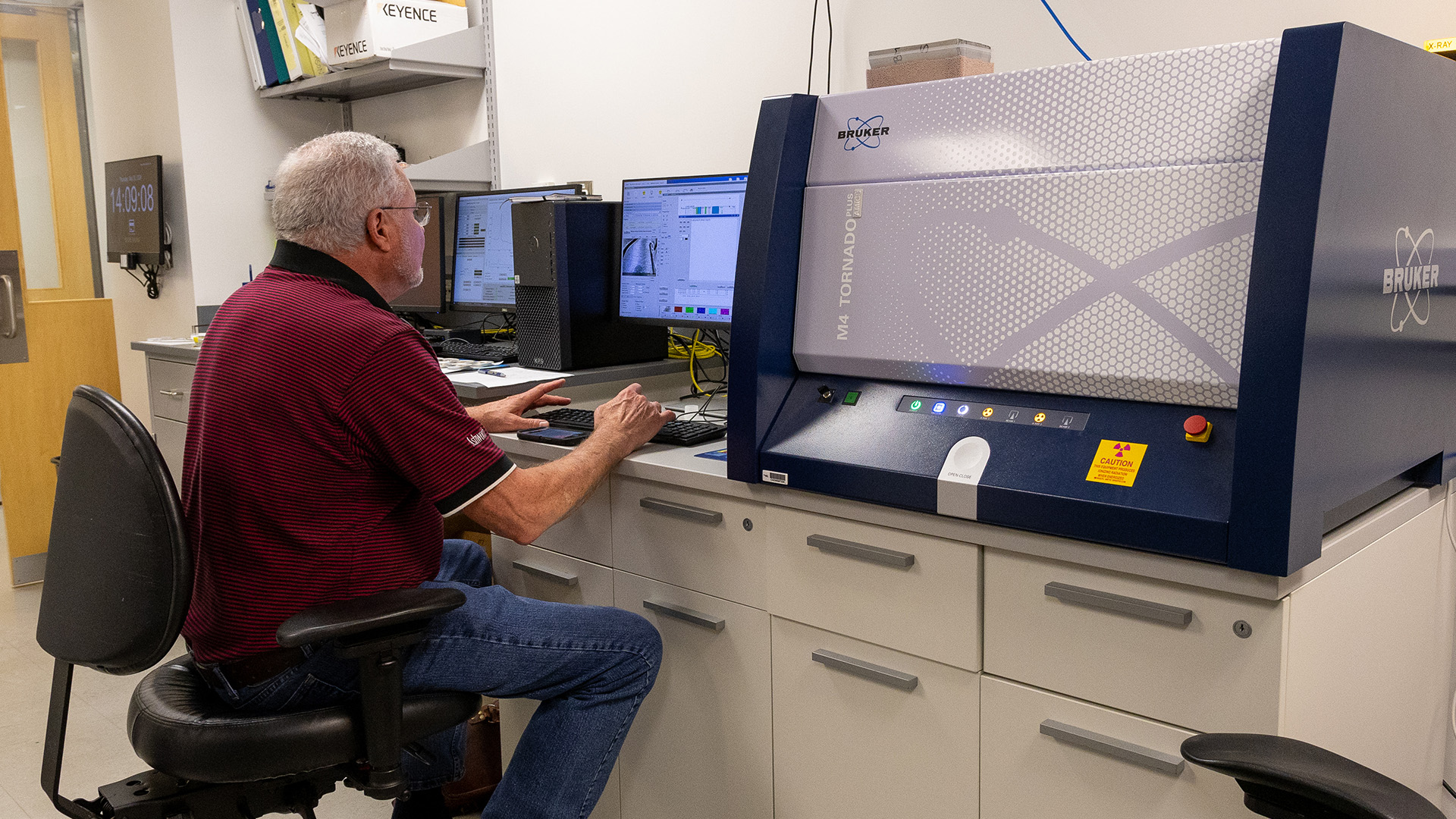

X-Ray

X-ray analysis at AMPF encompasses a range of advanced techniques for examining the elemental and structural properties of materials. This comprehensive approach allows for the detailed characterization of powders, bulk materials, and thin films. Our state-of-the-art tools and methodologies enable precise and accurate analysis, supporting innovation and excellence in material science.

X-Ray Diffraction (XRD)

XRD is used to analyze crystal size and composition, providing insights into the structural properties of materials. This technique is crucial for understanding material phases and crystalline structures. Featured tool: Rigaku MiniFlex XpC – COMING SOON.

Advanced XRD

This capability includes user-selectable parallel beam and Bragg-Brentano optical configurations for versatile scanning geometries. It supports high-energy-resolution 2D measurements, enabling superior qualitative analysis. Featured tool: Rigaku SmartLab system – COMING SOON.

X-Ray Fluorescence (XRF)

XRF provides highly sensitive elemental analysis with low background interference, capable of detecting elements from beryllium (Be) to uranium (U). It is essential for quantitative mapping and microanalysis. Featured tool: Rigaku ZSX Primus IV Sequential Wavelength-Dispersive X-ray Fluorescence Spectrometer – COMING SOON.

X-ray Microscopy/Computed Tomography (CT) or X-Ray CT

X-ray CT offers in-depth dimensional analysis and high-resolution imaging of small to medium-sized parts. It can identify microscale defects, making it ideal for detailed inspection and quality control. Featured tool: Zeiss Metrotom 800CT.